The Life Cycle of Your Fresh Coffee Beans | A Look At What It Takes to Grow Them

Coffee is a fruit -- an extremely precious fruit. It takes at least 200 coffee cherries to brew the 50 ounce pot of coffee you

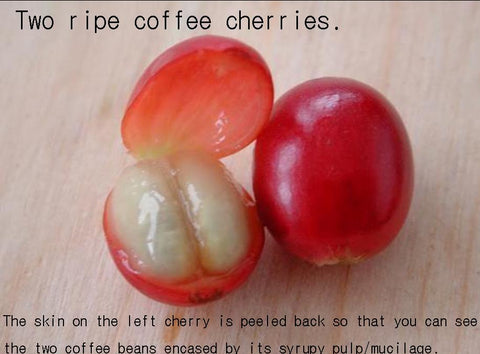

enjoy each day. (Each cherry contains two coffee beans [seeds]. I measured out how much coffee I would typically use to brew a 50 ounce pot of coffee and counted 411 of our roasted Brazilian Montanha de Diamante beans.) Before these cherished whole coffee beans arrive at FosterHobbs Coffee Roasters in High Point, NC, many hands--skilled and dedicated--planted, pruned, weeded, picked, peeled, washed, dried, hulled and bagged these coffee cherries grown in equatorial countries situated between the Tropic of Cancer and the Tropic of Capricorn.

enjoy each day. (Each cherry contains two coffee beans [seeds]. I measured out how much coffee I would typically use to brew a 50 ounce pot of coffee and counted 411 of our roasted Brazilian Montanha de Diamante beans.) Before these cherished whole coffee beans arrive at FosterHobbs Coffee Roasters in High Point, NC, many hands--skilled and dedicated--planted, pruned, weeded, picked, peeled, washed, dried, hulled and bagged these coffee cherries grown in equatorial countries situated between the Tropic of Cancer and the Tropic of Capricorn.

Mike and I deal with beans each day so we’re aware of the intricate preparation that occurs for each bean we roast, bag and sell. You, on the other hand, appreciate the flavor that perks you up in the morning or soothes you on a rainy afternoon but are perhaps oblivious to the meticulous, pain-staking processes that begin and maintain the life-cycle of the fresh roasted coffee you enjoy (similar, perhaps to the many times I have downed a bag of movie popcorn without realizing that it once waved in the wind on stalks with other future popcorn kernels).

In honor of Arbor Day 2015 and, more importantly, to honor and showcase the devotion of the people who ensure that our green beans arrive at our roastery safe and sound, we are sharing with you, our beloved customers and friends, the life cycle of your coffee bean.

If you are interested in the “preparation” processes that occur before you buy your fresh coffee beans online or at our roastery, read on.

Note: The explanation is slightly generalized because each coffee origin has a different harvest season and utilizes various processing methods, depending on climate and geography.

For the sake of simplicity, the life cycle of your coffee beans is divided into six different stages:

Sapling, Flower, Green Cherry, Ripe Cherry, Processed Bean, and Roasted Bean.

SAPLING -

Once the seed is planted and the seedling matures into a sapling, it is nurtured for approximately one year in nurseries to receive ample sunlight and climate protection before being transplanted to the main farm. Each tree produces approximately 1.1 pounds of coffee per year (Cooper Coffee Company, 2011). That’s a little more than each of the roasted 12 ounce bags of FosterHobbs Coffee you purchase online or at our roastery. So, as you can imagine, we are talking about acres and acres and millions of trees being planted and cultivated each year.

FLOWER -

Coffee is a self-pollinating plant which is produced from a magnificent display of honeysuckle-like blooms. Each year (depending on coffee origin) millions of flowers bloom for a few days, just after the area’s initial heavy rains; then, the flowers whither and fall off the trees. The flowering is a critical part of the growing cycle since a node will form where each flower bloomed. From each of these nodes a single coffee cherry, which contains the precious coffee beans that we enjoy each day, will form.

GREEN COFFEE CHERRY -

Green coffee cherries, developed from each node left by the fallen flower, grow for six to eleven months, depending on the length of the country’s rainy season. In Costa Rica, for example, where the rainy season lasts for seven months, the green cherries are nourished and nurtured typically by four to six hours of rainfall each day. (With that much rain, the farmers, as you can imagine, are not just watching the cherries grow, they are busy controlling erosion, managing drainage channels and maintaining roads on the farm, not to mention pruning, weeding, and tending to nursery trees).

RIPE COFFEE CHERRY -

With the end of the rainy season, comes the ripening of the coffee cherries. The large green cherries will turn either yellow or red, depending on the varietal, and fill with the sweet mucilage (pulp) that surrounds the seed. Unlike the flowering process, the ripening process is slow and unsteady. Not all cherries ripen at the same time as you can see in the photo below.

Particular care must be taken to ensure that only ripe cherries are picked (this noticeably affects the taste of the coffee). Because the cherries are not harvested at one time, each tree can be picked up to five times. As I am blending the beans, I daily think of the skill and patience of those who pick only the cherries perfect for processing because, to be honest, on some days, I may be tempted to just grab them all and throw them in my bucket. It has helped me to value the quality of each bean rather than the quantity of them. And while these farmers are being as precise as possible in regard to the particular cherries they are picking, consider the terrain where coffee trees are cultivated. All specialty grade Arabica cherries (the only grade and variety we roast) grow in trees on mountainsides at higher elevations --underneath the protection of shade trees – NOT on flat, solid land grown in tidy, roomy rows, so picking the cherries is more difficult than harvesting tobacco or sweet potatoes, for example. Needless to say, every FosterHobbs Coffee bag I fill, I remember to thank the Lord for these beans and for the farmers who cultivated them.

Particular care must be taken to ensure that only ripe cherries are picked (this noticeably affects the taste of the coffee). Because the cherries are not harvested at one time, each tree can be picked up to five times. As I am blending the beans, I daily think of the skill and patience of those who pick only the cherries perfect for processing because, to be honest, on some days, I may be tempted to just grab them all and throw them in my bucket. It has helped me to value the quality of each bean rather than the quantity of them. And while these farmers are being as precise as possible in regard to the particular cherries they are picking, consider the terrain where coffee trees are cultivated. All specialty grade Arabica cherries (the only grade and variety we roast) grow in trees on mountainsides at higher elevations --underneath the protection of shade trees – NOT on flat, solid land grown in tidy, roomy rows, so picking the cherries is more difficult than harvesting tobacco or sweet potatoes, for example. Needless to say, every FosterHobbs Coffee bag I fill, I remember to thank the Lord for these beans and for the farmers who cultivated them.

PROCESSED BEAN -

Once the cherry is picked, it is taken to be processed in a mill where they are selected, sorted, peeled, washed and dried.. There are three processing techniques used by coffee farmers: wet-processing, dry-processing and semi-dry processing. The processing of the coffee cherry is just as important as the picking and maybe more tedious (I liken the process of separating the two beans that are contained in the cherry, surrounded in its sticky pulp, to peeling a grape that would contain two large seeds.)

In the wet-process (washed coffee), the skin and pulp are removed before the fruit is dried. This process requires specific machinery and a substantial amount of water. The coffee cherries are immersed in water. Bad or unripe fruit will float and the good, ripe fruit will sink. The bad fruit is discarded while the remaining pulp is removed from the coffee bean through microbes in fermentation or scrubbed off with special equipment. The coffee beans are then dried by the sun on tables or on patios. The beans are carefully circulated and raked to avoid mildewing or any tainting of the beans’ flavors. Before being bagged for shipment, the outermost parchment skin of the bean that remains is hulled.

In the dry process (also known as unwashed or natural coffee), the entire cherry is first cleaned and then placed in the sun to dry on tables or in thin layers on patios. As described with the wet-process, the beans are circulated and carefully raked to avoid mildew and to ensure that the beans dry evenly. The beans are watched closely because overdrying can cause the beans to become dry and brittle, making them break easily in the final hulling operation. And underdrying can be detrimental too. Beans that are insufficiently dried and bagged are prone to fungal or bacterial attack.

In the semi-dry process, a hybrid process of the two methods previously explained, the outer skin of the coffee cherries are removed mechanically. The coffee beans, still coated with pulp, are stored for up to a day. Then the pulp is washed off, leaving the thin parchment skin on the bean and the parchment coffee is partially dried in the sun. This process is also called wet-hulled or semi-washed process.

No matter what the processing method is used, the Arabica coffee beans go through final cleaning, another sorting and are graded (based on size, color, absence of defects, cup quality, etc.) before being bagged and shipped to FosterHobbs Coffee. Since we only roast coffee that receives the classification of Specialty Grade (coffee that receives a score of 80 or above are classified as Specialty Grade), we are particularly appreciative of the extra care it takes to produce our beans.

ROASTED BEAN -

Your coffee is now closer than ever for you to enjoy. At least it is in the same country. Once the coffee is delivered and acclimated to our roastery environment, it is roasted in our Ambex small batch drum roaster at temperatures of 418 - 465 degrees Fahrenheit (as roast profiles dictate), depending on the beans' origin, density, moisture level, and processing method. Roasting is what unlocks the flavor of your beans. (We immediately start thinking of these beans as yours. Being a young coffee roasting company we know who you are. As we grow, we will work to ensure that this attitude never changes.)

All of those years flying, learning and knowing how air and temperature affects performance, has proven an advantage for Mike, specifically, in his approach to roasting. And, as we daily cup beans to analyze his roasting profiles, I am amazed at how intuitively he gauges chemical reactions of the various beans. (Enough bragging on my husband’s skill. He doesn’t know that I have inserted this section, so please don’t tell him.)

After the coffee bean is roasted, its weight has reduced and its size doubled. To protect the flavor, body, and aroma of your gourmet coffee beans, we lovingly store, hand-blend and bag them. We believe, as you now know, that each part of the growing and processing cycle is critical, so we take the same care in the roasting, blending, storing and bagging processes as all the farmers did so that you will enjoy the consistent, exceptional flavor in each cup you drink.

Every day, we feel honored to be a part of this chain of events that must occur so that you can brew and enjoy specialty grade coffee in the comfort and convenience of your home, office, dorm, hotel, campsite, car, etc. We hope you know that it is our desire to match the devotion of each person that planted, watered, pruned, weeded, hulled, etc. the precious beans that you buy from FosterHobbs Coffee. As you can see, it is a chain of painstakingly meticulous and laborious measures to grow, process and roast coffee and we don’t take any of it for granted. It is our hope that you taste the difference of our devotion, as well as the devotion of all those who handled the gourmet coffee beans prior to us. We thank you for the opportunity to serve you! Enjoy!

Every day, we feel honored to be a part of this chain of events that must occur so that you can brew and enjoy specialty grade coffee in the comfort and convenience of your home, office, dorm, hotel, campsite, car, etc. We hope you know that it is our desire to match the devotion of each person that planted, watered, pruned, weeded, hulled, etc. the precious beans that you buy from FosterHobbs Coffee. As you can see, it is a chain of painstakingly meticulous and laborious measures to grow, process and roast coffee and we don’t take any of it for granted. It is our hope that you taste the difference of our devotion, as well as the devotion of all those who handled the gourmet coffee beans prior to us. We thank you for the opportunity to serve you! Enjoy!

SOURCES:

Hacienda La Minita "A Costa Rican Farm," Rao, Scott "The Coffee Roaster's Companion," Robinson, Matt "The Coffee Lover's Handbook"